Our Products

wiring harnesses color sequence detector LJL-SE2

Technical specification

| Model | LJL-SE2 |

| Trigger | Auto trigger |

| Detection accuracy | High precision |

| Rated power | 35W |

| Wire placement requirements | Arbitrarily placed |

| Support output | FM-9A supports I/O output |

| Features | Small size and light weight |

| Dimensions | 430*300*430mm |

| Weight | 8.5kg |

| Functions | Identify the color of the wire, determine whether the position is correct, determine whether the wire terminal hole is inserted incorrectly or in place, the automatic wire harness is in poor wire position and alarm NG |

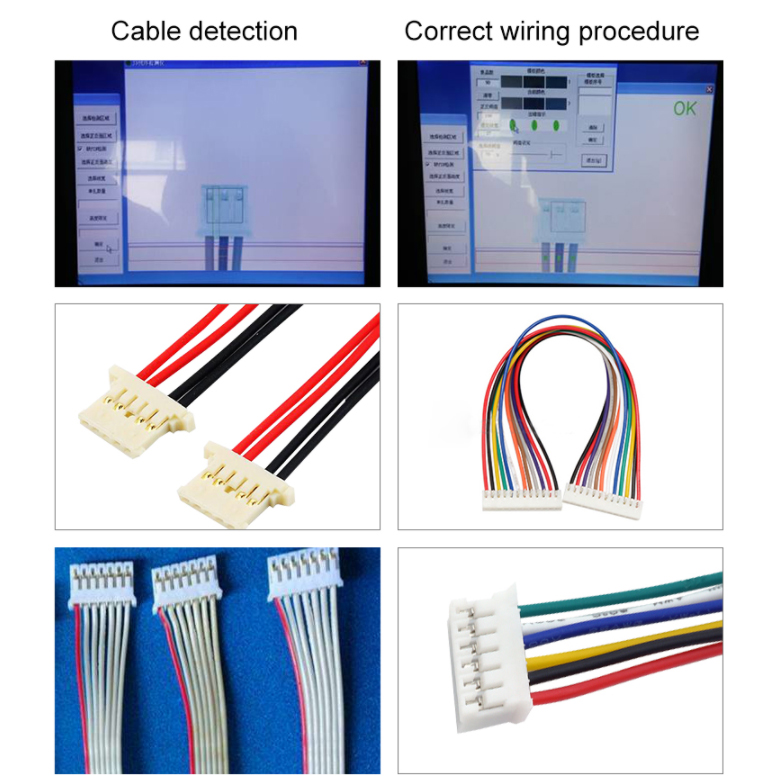

Harnesses in terminal connectors usually need to be arranged in a certain color order, and manual inspection often leads to misidentification or omission due to eye fatigue. The line sequence detection device adopts visual technology and intelligent algorithm to determine whether to meet the predetermined standard and automatically identify the color order of the wire harness, so as to ensure the correct wiring order. When using this machine for line order detection, you only need to place the product within the detection area can be normal, do not have to distinguish between the right surface of the product.

Harness color line sequence tester

Used to detect the correct discharge order of the different colors in the cable harness. Wire color detection, wire color, line sequence detection, terminal line sequence detection, wire harness color detection, connection wire color, wire harness sequence detection, line sequence detection, wire harness sequence detection device.

Wire harness Cable has been widely used in computers, automobiles, mechanical equipment, aerospace and other fields. Quality and efficiency are the topics that every Cable manufacturer pays close attention to. In the production process, the color sequencing requirements are all produced according to the standard, most of the production. The operator uses the operator to observe through the eyes, and the leak detection and the wrong inspection occur during the long-time detection work, which leads to the failure of the inspection quality (also detected by the electric measuring machine).

The wire harness color recognition detector is an intelligent visual inspection device independently developed by LI jun le Company and specially designed for cable manufacturers to detect whether the wire harness sorting meets the standard requirements and automatically detects and outputs the detection result signal. The detector automatically sorts the color by computer processing. It does not require the operator to identify through the eyes. In the daily work, the product is placed on the test fixture. The instrument can automatically identify the good and the defective products, and the NG displays the position of the wrong plug. Whether it is automatic trigger or external contact device, it has the function of sound alarm, which greatly improves the speed of detection and the quality of inspection. It is the best choice for enterprises to improve production inspection efficiency, strictly control product quality and save labor costs.

Specific product advantages:

1.The operation is simple, the user can use it directly, and you can learn to operate within 20 minutes.

2.The machine has a long service life, 35W low power consumption, and 5 times that of a normal pc machine.

3.Standard system, with strong stable versatility, and all wiring bundles can be detected.

4.Strong anti-interference ability, characters on the wire harness, and color ring. All are detectable without affecting the test results.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed