Our Products

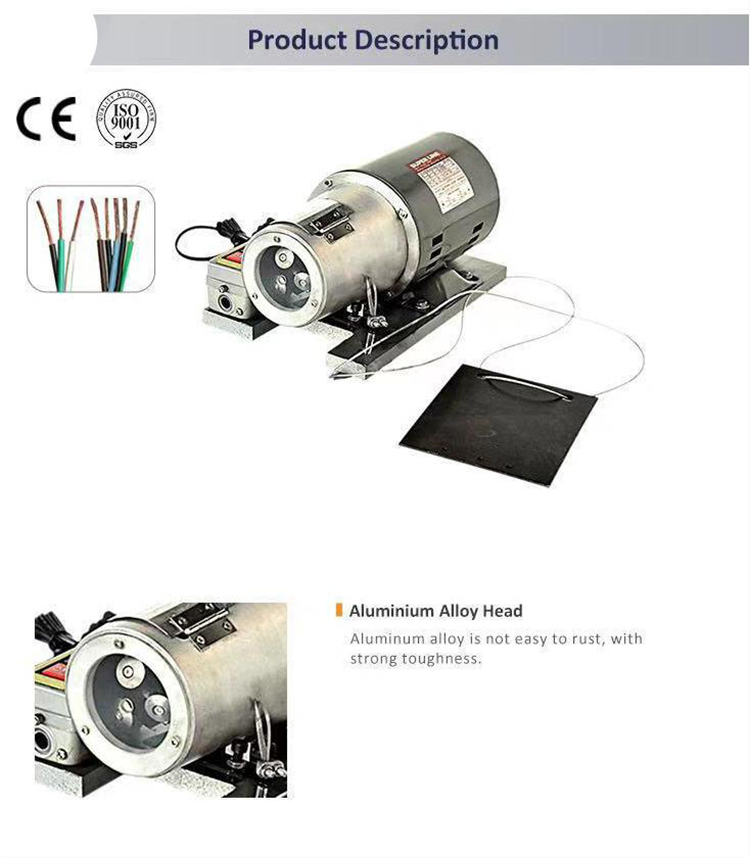

Wire Stripping and Twisting Machine LJL-200

Specification

- Used for stripping and twisting wires

- Stripping length: 2-30mm

- Wire size: AWG14-22

- Power Rating: 120W

- Weight: 15kg

- Measurement: 300*200*160mm

- Suitable for: AV / DC power line, electronic line, multi center line, rubber line, isolation line

Features

1. Special mechanical structure, twisted wire, once completion

2. Special spring hook, twist the end is thin, not easy to loosen

3. Single-core twisted wire with period specification of 22AWG-14AWG

4. Suitable for: AV/DC power cord, electronic wire, multi-heart wire, rubber wire and isolation line

Operating instructions

1、 Operating instructions

1). Connect the power supply, pull down the position about on, and the motor will drive the tool holder to rotate.

2). The incoming line direction as shown in the figure; Put the wire to be processed into the acrylic wrench hole until it touches the positioning shaft.

3). When the pedal is pressed, the chain drives the rocker arm, and the lever principle is used to push the cam forward, while the cam uses the slope principle to concentrate the cutter rocker arm to the center, and the blade and wire torsion spring can cut the skin and twist the wire.

4). Pull out the wire without releasing the pedal, which is the peeling work, and then release the pedal.

5). Complete the wire processing procedure one by one from the process in 2.3.4 above.Remarks: when the motor starts running, the temperature will rise to about 60 ℃, and it will be kept at a constant temperature

2、 Functional explanation of each part

1). Positioning shaft: this shaft is used for positioning, and the positioning of processing length can be adjusted by itself.

2). Adjusting screw of positioning shaft: it is used to fix the function of positioning shaft. The positioning shaft can be adjusted only after the screw is put in place, and then locked after adjustment.

3). Tool holder fixing screw: it is the function of fixing the tool holder on the spindle.

4). Knife edge adjusting screw: that is, adjust the wire diameter. The larger the gap between the screw and the base plate, the thinner wire can be processed, and the smaller the gap, the thicker wire can be processed.

5). Rocker arm: push the bearing and cam to make the cutter rocker arm move as expected.

6). The foot pedal should be fixed at about 20-30 degrees.

7). When the blade reaches the cutting position, the wire torsion spring presses down on the wire sheath by about 0.4-0.5mm.

3、 Troubleshooting method for poor twisted wire:

In case of poor wire twisting, please check:

1). Check whether the blade is worn.

2). Check whether the torsion spring behind the blade is broken or deformed. Please correct or replace it yourself.

4、 Maintenance instructions:

Fill the sliding joint with lubricating oil regularly and keep the machine clean.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed