Our Products

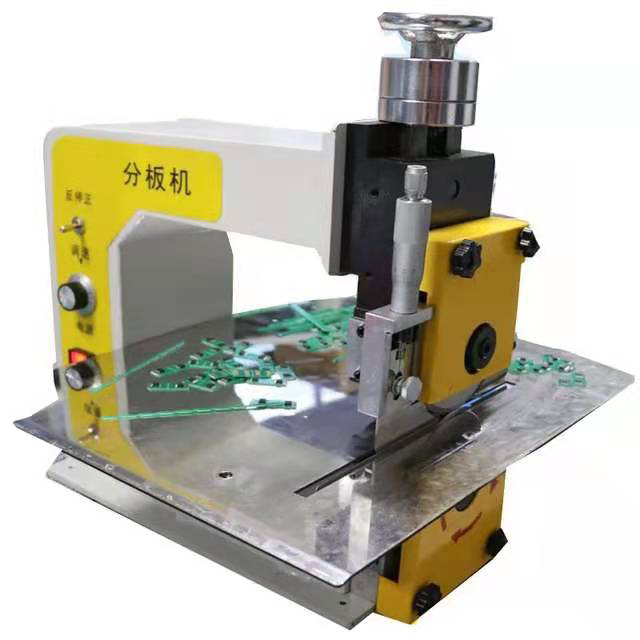

VPCB cut separator machine LJL-908

products video

Descriptions

Model: LJL-908

Control system:Smart ARM system

Moving from: Fully automatic go board type

Blade material:SKD-11 high-speed steel material

Cutting thickness:0.6mm-3.0mm

Power supply:AC 220V /50HZ

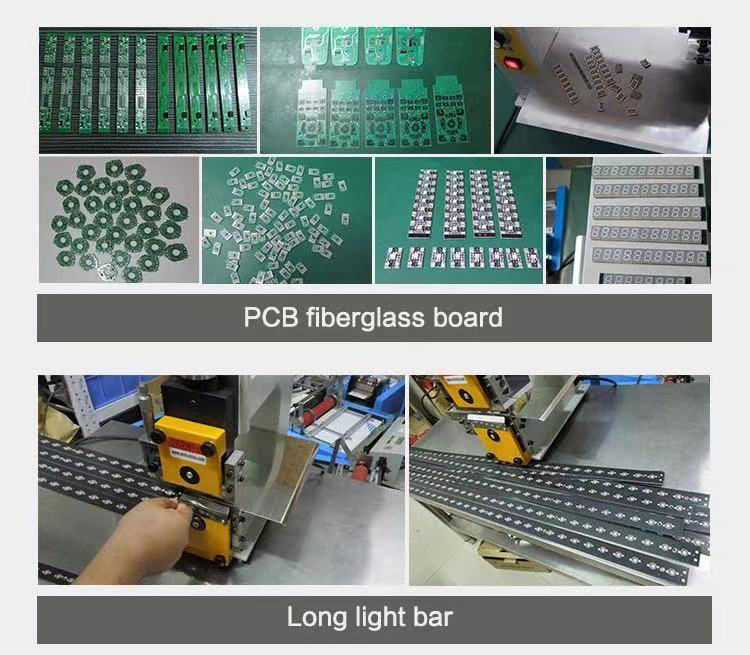

Application:Circuit board, aluminum substrate, glass fiber board, etc. segmentation cutting

Power:40W

Size:L300*W240

Weight::30KG

| Product name | LJL-908 | LJL-908U (Upgraded version) | LJL-908L ( Lengthen version) |

| Picture |  |

|

|

| Control system | Smart ARM system | ||

| Moving from | Fully automatic go board type | ||

| Blade material | SKD-11 high-speed steel material | ||

| Cutting thickness | 0.6mm-3.0mm | ||

| Power supply | AC 220V /50HZ | ||

| Application | Circuit board, aluminum substrate, glass fiber board, etc. segmentation cutting | ||

| Speed | 0~200mm/s | 0~200mm/s | |

| Power | 40W | 60W | 90W |

| Size | L300*W240 | L400*W310 | L1500*W450 |

| Weight | 30KG | 35KG | 45KG |

Products Description

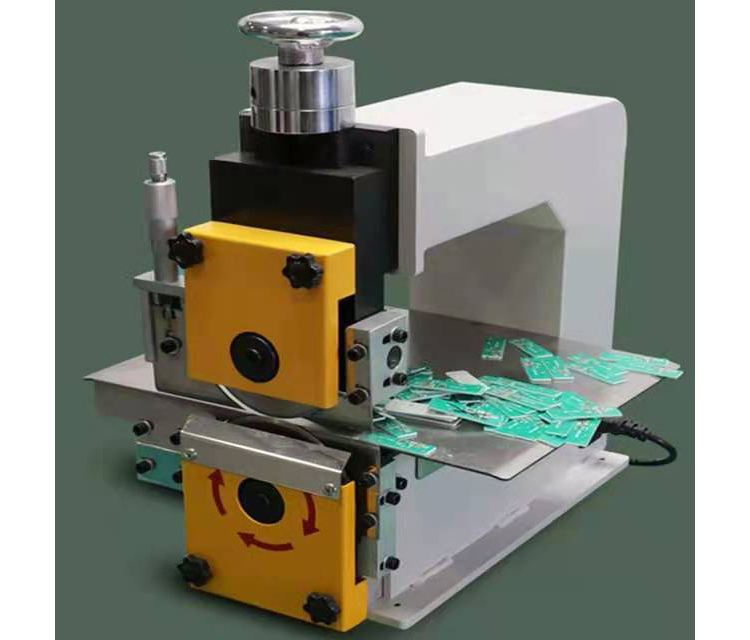

1. Use machine cutting to reduce stress and prevent solder joints from cracking

2. Manually adjust the height of the upper guide piece to solve the problem of different cutting depths

3. Use V groove to guide when dividing to ensure product quality.

4. High efficiency: max=200mm/S, and the speed is adjustable

5. High accuracy, easy maintenance and high safety

6. The machine is small and easy to operate

7. Adjustment range of upper tool holder: 0~15mm

Machine characteristics

Precision track, can fine-tune the centimeter lift of various PCBs to solve the V-slot depth problem.

It is equipped with two upper and lower tungsten steel blades, which are durable and durable. Cut off without dragging.

High precision, easy maintenance and high safety.

The speed can be controlled and adjusted according to the length and shortness of the PCB.

The machine is light, does not take up space, and is easy to operate.

Machine segmentation

HOT-SALE PRODUCT

Quality First, Safety Guaranteed