Our Products

Ultrasonic wire-beam welding machine LJL-X20

products video

Principle introduction

Ultrasonic welding is the process of converting the current into electrical energy through an ultrasonic generator. The converted high-frequency electric energy is then converted to the same frequency through the transducer, which is transmitted to the weld head through a set of horn devices that can change the amplitude. The vibration energy received by the weld is transmitted to the connector of the piece to be welded. In this region, the vibrational energy is converted to heat energy by friction, and the plastic melts. Ultrasonic waves can be used not only to weld hard thermoplastic plastics, but also to process fabrics and films. Thermal energy comes from the reciprocating movement of the workpiece at a certain pressure with a certain displacement or amplitude on another surface. Once the desired degree of welding is reached, the vibration stops, while there is still some pressure applied to the two workpieces to cool and solidify the freshly welded parts, thus forming a tight binding.

functional characteristics

LJL-X20 series is a new generation of wire harness machine with strong structure and joint area up to 40mm2. Its lightweight and precise design is most suitable for non fixed working environment, that is, the same version of the harness machine can be used for desktop, plate or mobile harness machine, so it also reduces the cost of users. Advantages: small volume and light weight. The same type of wire harness machine has plate type and table type interchange function. The lower cost storage and spare parts welding section is from 0.2 square mm to 40 square mm. The operation is safe and stable. The automatic proofreading function is easy to maintain. The operation and replacement tools are simple, fast and safe. The structure is simple and precise, High operation safety, innovative installation system reduces the weight of equipment, and can communicate with multiple machines. The power supply is 2000W to 4000W.

Model: LJL-X2020

Frequency: 20K

Output power: 2000W

Supply voltage: 220 V, 50 / 60 Hz

Maximum current: 15A

Supply standard: 6.5bar (94 psi) clean, dry compressed air

Control form: Single Chip Microcomputer

Box size: 500 * 400 * 120mm

Frame size: 340 * 180 * 242mm

Maximum welding capacity: 16mm2

Model: LJL-X2030

Frequency: 20K

Output power: 3000W

Supply voltage: 220 V, 50 / 60 Hz

Maximum current: 15A

Supply standard: 6.5bar (94 psi) clean, dry compressed air

Control form: Single Chip Microcomputer

Box size: 500 * 400 * 120mm

Frame size: 340 * 180 * 242mm

Maximum welding capacity: 25mm2

Model: LJL-X2040

Frequency: 20K

Output power: 4000W

Supply voltage: 220 V, 50 / 60 Hz

Maximum current: 30A

Supply standard: 6.5bar (94 psi) clean, dry compressed air

Control form: Single Chip Microcomputer

Size of electric box: 550 * 420 * 220mm

Frame size: 470 * 220 * 262mm

Maximum welding capacity: 40mm2

High quality characteristics of the equipment system (technical characteristics of ultrasonic generator)

- It can set time and power to ensure stable welding quality.

- Limits of extended process control

- The range of full vibration amplitude is 0-100% adjustable and provides constant power.

- Over temperature protection

- Over current protection

- Overload protection

- Real time automatic frequency adjustment with memory

- Self diagnosis and display, sound alarm, logic electrical signal output (used to control other automation equipment)

- Display the information of the fault location directly, so as to facilitate troubleshooting

- International standardized interface RS485, which can be used for communication equipment with external PC

- Digital delay trigger. Accurately control the time of ultrasonic wave to ensure the stability of welding.

- Characteristics of wire harness welding machine

- The section density of ultrasonic welding part is better and it is not easy to form cavity.

- The resistance coefficient of ultrasonic welding is very low or close to zero, the conductivity is better, and the service durability is improved.

- Ultrasonic welding will not produce heat accumulation, which will lead to local temperature rise, forming metal workpiece burning and other quality hazards.

- Ultrasonic welding is less affected by external moisture, dust, oil and gas and other adverse factors, and it is not easy to produce adverse conditions such as corrosion and oxidation of metal parts, resulting in poor electrical conductivity, The degradation of signal transmission performance.

- Ultrasonic welding for metal parts, after long-term use, will not cause the decline of electrical conductivity due to corrosion and oxidation of copper wire inside the welding point, resulting in functional failure.

- Ultrasonic welding can minimize the temperature effect of the material (the temperature of the welding zone does not exceed 50% of the absolute melting temperature of the metal to be welded), so as not to change the metal structure,

- So it is very suitable for welding application in electronic field.

- Compared with resistance welding, ultrasonic welding has the advantages of long service life, less time of repair and replacement, and easy to realize automation.

- Ultrasonic welding can be carried out between the same metal and different metals, which consumes much less energy than electrical welding.

- Ultrasonic welding is the most advanced, convenient, environmental protection and energy-saving electrical connection technology

- Low requirement for welding metal surface, oxidation or electroplating can be used for welding

- Short welding time, without any flux, gas, solder

- No spark, close to cold welding machine

- The minimum requirement of preparation before welding can save labor

- A simple process ends in one second.

- Low cost investment and mold replacement cost

- Lightweight ergonomic design, durable welding force, two shell

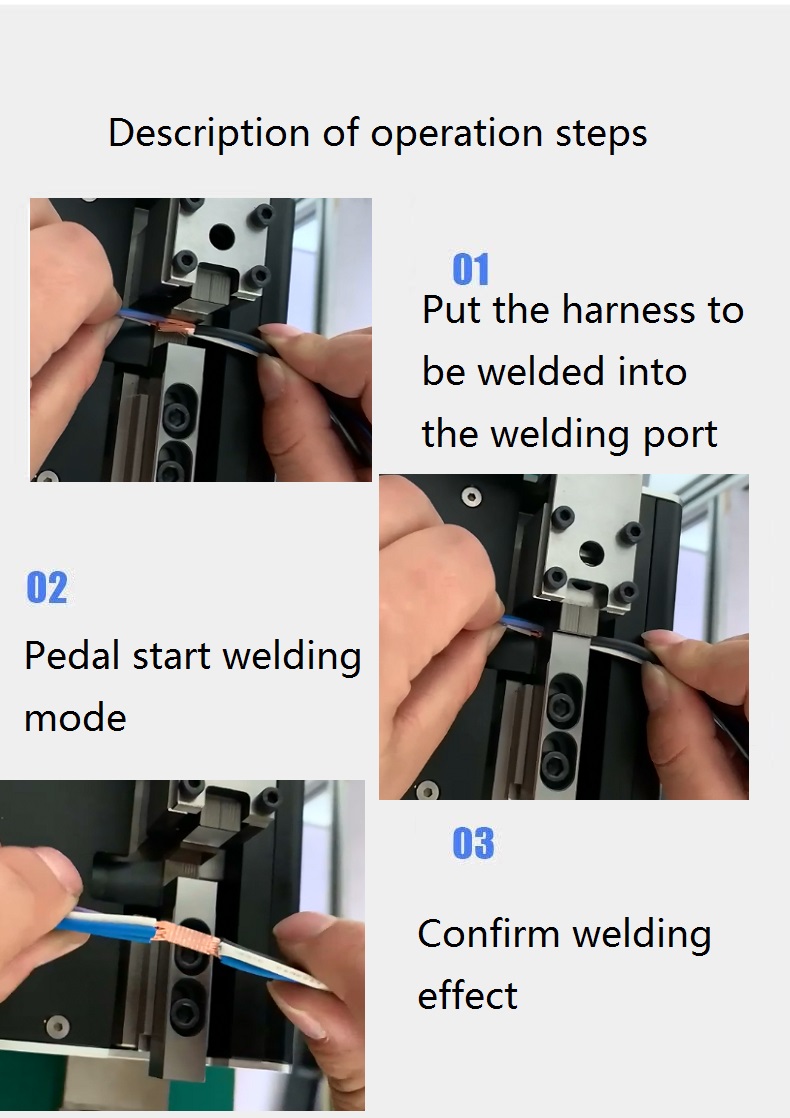

Easy to use

The integrated system and constant welding parameters ensure the welding quality

There is no need for skilled workers, the use of equipment only needs one day of training

Mold replacement is simple and fast, no need to recalibrate, reduce downtime and production costs

Easy to install, maintain and operate

HOT-SALE PRODUCT

Quality First, Safety Guaranteed