Our Products

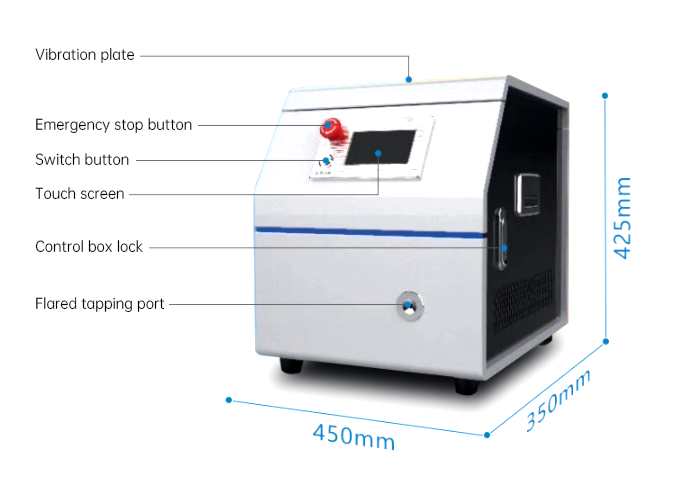

Pipe-shaped Pre-insulated Terminal Crimping Machine LJL-12

products video

Terminal crimping machine for heat shrink

Tubular wire terminal stripping crimping machine semi-automatic insulation terminal crimping machine

Auto feeding ferrule terminal stripping crimping machine 0.5-4mm2 terminal crimping machine

| Model | LJL-12 |

| Control mode | human-machine interface, electronic control, pneumatic control |

| Operation mode | Automatic trigger operation and manual operation |

| Wire size | BVR wire 0.5,0.75,1.0,1.5,2.5,4.0mm2 |

| Stripping length | Max.17mm |

| Terminal size | Insulator length ≤7.5mm,conductor length≤10mm |

| Crimp Shape | Quadrilateral Crimp |

| Production capacity | 2.5s /wire |

| Air supply | 0.6-0.8Mpa |

| Working temperature | 10~25℃ |

| Working humidity | 30 ~ 80% HR (no condensation) |

| Terminal specification | tubular pre-insulated terminal, insulator (round) length less than 7.5mm |

| Production capacity | 2.5s/line (regarded as single operation cycle of the machine) |

| Power supply | external input power supply AC220V0/60HZ10A; Internal power supply DC24 V, DC12 V |

| Air pressure | 0.6-0.8MPA |

| Power source | AC220V/110V/50/60HZ |

| Weight | 40KG |

| Dimensions | W350mm×L450mm×H400mm |

Feature

1. Simplify complex procedures, improve overall efficiency significantly, and have a large cost advantage.

2. The terminals within the specified range do not need to replace the vibration plate, and instantly change the different terminal specifications.

3. Inserting, stripping and crimping are completed at the same time, mainly for crimping tubular terminals of international standards.

4. The projected part of the wire adopts the shape of the bell mouth to facilitate the inserting.

5. Automatic stripping wire diameter and crimp height adjustment.

6. Adopt sensitive pneumatic induction control, fast crimping.

7. It adopts the feeding method of vibrating plate, which makes the terminal replacement convenient and quick.

8. Imported components and cylinders are used for stable performance.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed