Our Products

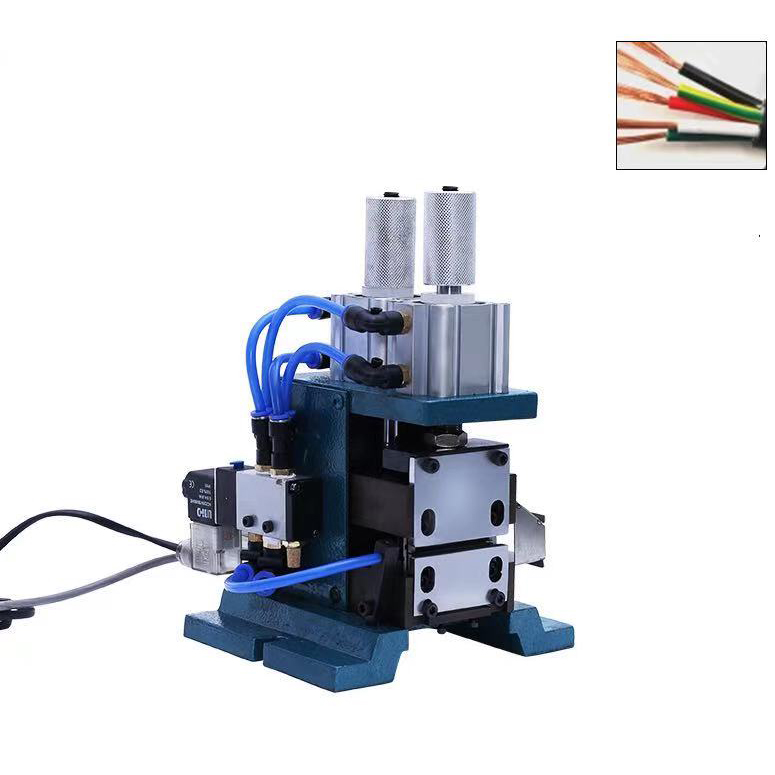

Multiple Hot Wire Stripping & Twisting Machine LJL-3FA

products video

Specifications

| Ability to peel twist | 1~10strips/time | |

| Stripping torque range | AWG#18~#32 0.1~0.75m² | |

| Minimum peel twist tength | 3mm | |

| Maximum peel twist tength | 25mm | |

| Stripping torque speed | 120~30times/minute(adjustable) | |

| Power supply | 220V 50Hz | |

| Power | 90W | |

| Air pressure | 4.75kg | |

| Weight | 15kg | 18Kg |

| Dimensions(L.W.H)mm | 300*200*280mm | 320x300x400 |

Features

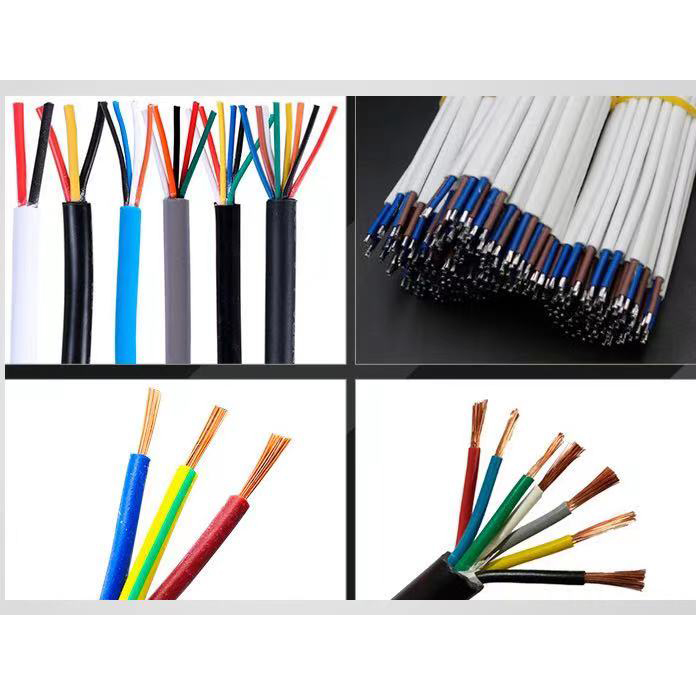

- The machine is suitable for line to coarse computer peripheral cable, telephone line, side line, audio cable, microphone cable, power lines, and twisting the tail stripping process;Multiple functions simultaneously so that the efficiency of stripping double twist, quality is more perfect;

- 1: Electric control, improved model, advanced design. Applicable wire diameter awg18-32.

- 2: The distance between the die and the clamp holder is short, so that the core wire or special short wire is easy to operate without scald or pinch.

- 3: Special structure, fast speed, all kinds of wires can be half stripped, full stripped, easy to adjust.

- 4: Double knife design, tangential peeling one-time completion type, take out a single knife can be applied to a single knife.

- 5: The blade can be heated, and the special wire can be stripped easily.

- 6: Liquid crystal design temperature, can be in constant temperature state.

3F peeling pper uses a solenoid valve to control the cylinder principle. The knife and the clamp seat distance is short, making the computer cable or particularly short wire easy to handle. Generally the processing of semi-peeling, full peeling of the end of the wire speed is fast. Improve the traditional computer core wire peeling right foot hand pull mode, and only one set of tools applies to the flat peeling and circular wire peeling of any line diameter, and only one set of tools. Special aluminum alloy body and cylinder, tough and wear-resistant and not easy to rust and corrosion, silent operation, ordered long command, light and easy to carry, (can replace a core line peeling machine + a half-peeling wire machine)

Features description

1. Gas-electric control, improved model and advanced applicable line diameter AWG#18-32.

2. The distance between the knife mold and the clip seat is short, which makes the computer cable or special short line easy to operate without scald or injury.

3. The special structure is fast, and all kinds of wires can be half peeled, fully peeled and adjusted easily.

4. Double-knife design, tangent peeling once molding, take out the cutting knife can be used with a single knife.

I. Scope of application

This machine is suitable for a kinds of single core conductor, cable, row, multiple core, power cord, power cord, coaxial cable, can realize full peeling, half peeling, intermediate stripping, multiple layer stripping function.

Second, the working principle

The machine uses cylinder as the power element, through special valve sequence control to clamp the tangent and peel automatic sequence.

The machine consists of clamp mechanism, tangent mechanism, fixed length mechanism and wire stripping mechanism. The clamp mechanism realizes the clamp fixation function of the wire, the cutting mechanism cuts the wire, the stripping length fixing the ruler function, and the stripping mechanism completes the outer stripping function of the wire. The machine adopts the foot switch operation, and coordinates the wire delivery and drawing work with both hands to improve certain working efficiency.

This machine is mainly for the DuoRui computer line, telephone line, side by side line and the tail peeling (cut off) of the power line processing, simple operation, wide use.

III. Use instructions

. Connect the intake air pipe to the gas source 4.5-7kg/ ㎝ 2

The power cord plug plugs into the 220V 50Hz power supply

Press the foot switch to move the cylinder

As shown in the figure, the two fine-tuning nuts are the key to operation: loosen the headless screw in the middle of the nut, nut 1 controls the upper and lower clips; nut 2 controls the blade mold to tighten the nut (counterclockwise) for different thickness and thickness.

Commissioning OK is to lock the headless screw in the middle, the tail main cylinder is the pull cylinder, the travel adjusting nut for the adjustment of the cylinder stroke, the shorter the forward travel (such as half peeling), the longer the future, the peeling adjustment OK will be the fixing nut lock. The two regulating valves on the cylinder are adjusted peeling. The speed of return shall be moderate for normal use.

The use of double-knife models is basically the same as above, designed for wire cutting molding. Pay attention to the following points:

a) The gap between the cutter and the peeling is 1.5mm

b) When increasing or decrease the gasket, observe the same upper and lower thickness to avoid the collision and damage

c) Increase or decrease the gasket according to the length of stripping, etc. When peeling 3.0mm, apply 1.5mm, 1.5+1.5=3.0mm

d) When the cutting knife is long for peeling, it can be used with a single knife. The peeling length is controlled by the gear line block.

Four. Maintenance instructions

1. Keep it clean for a long time

2. The slide rail is the main active part, with lubricating oil once a day

3. Keep the clip block clean without oil pollution to maintain the strength of the clip

4. Cut off the power supply and gas source completely

5. Provide a three-point combination at the gas source

Pneumatic Cable Stripping Peeling Machine Wire Stripper

Multi-line Pneumatic Cable Stripping Peeling Machine Wire Stripper

Pneumatic wire cable peeling machine for multicore cable with CE

copper cable wire stripper Automatic tinned copper wire stripping machine

Pneumatic Wire Stripping Machine

HOT-SALE PRODUCT

Quality First, Safety Guaranteed