Our Products

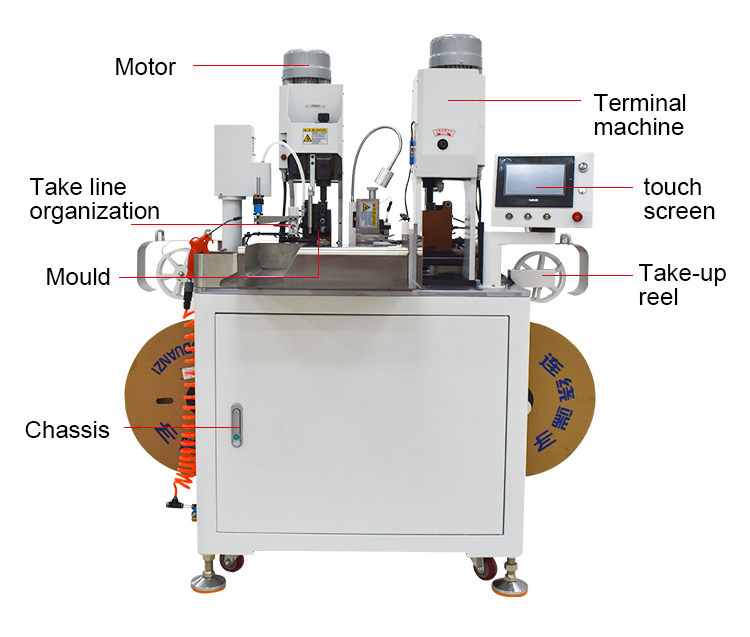

Fully automatic double sides terminal crimping machine LJL-QS201

products video

Fully automatic double head terminal machine

Fully automatic double sides terminal crimping machine

| Product Model |

Fully automatic precision double-head terminal machine LJL-QS201 |

| Product name |

Fully automatic double head terminal machine |

| Machine size |

L 1380 * W 750 * H1600(mm) |

| Voltage |

AC220V 2.5KW |

| Working air pressure |

0.5-0.7Mpa |

| Processing capacity |

200mm same as 4800 strips/hour |

| Function |

Cutting wire, stripping wire, single-side crimping, double-head crimping. |

| Processing Length |

25-9999 mm, can be customized 25mm |

| Stripping length front |

0-12mm |

| Stripping length rear end |

0-8mm |

| Processing line material range |

AWG18#-32# |

Fully automatic double head terminal machine

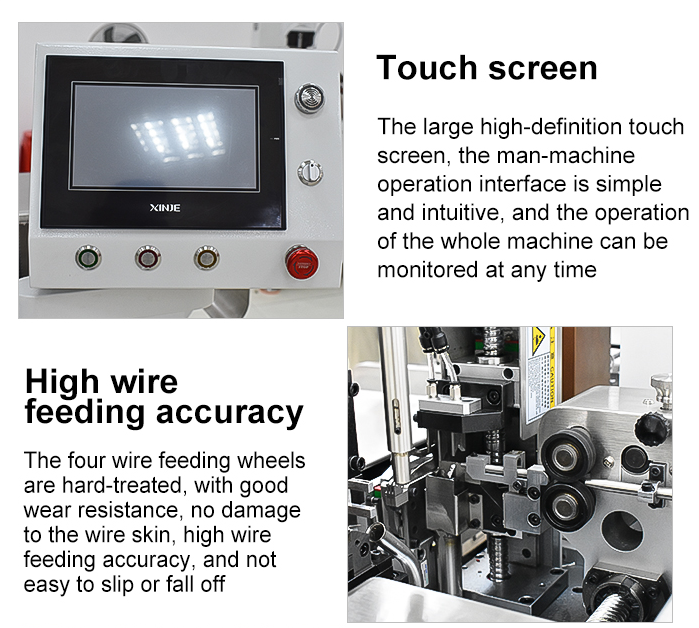

Support single and double end stripping and crimping terminals, feeding accuracy is small, the stripping doesn’t damage the core wire, stable operation, low defective rate. Applicable with horizontal and direct die, high crimping precision.

1. A multi-functional automaton. set cutting, peeling, single head pressure terminal, double head pressure terminal as one of the precision high-end automaton

2. Advanced software and touch screen technology make it easy to operate. All parameters of the machine are completed on the display screen

3. Strong, durable, stable, efficient, energy saving. The raw materials of this machine are treated by heat treatment and hard oxidation

4. The whole machine is equipped with 5 sets of Mitsubishi servo, which can meet the processing needs of customers to a greater extent and has stronger precision

5. Equipped with complete detection functions. missing line detection, wire knotting, crimping detection, air detection, etc. It is equipped with all the pressure detection devices in the market

6. The crimping position adopts ultra quiet terminal machine, with low noise and uniform force. It can be equipped with horizontal mold, straight mold and flag mold

Parameter configuration of high speed full servo double head machine LJL-GS201

Parameter configuration of high speed full servo double head machine

Machine model:LJL-GS201

Appearance size: L 1380 * W 750 * 1580 H (mm)

Machine weight: 360Kg

Working voltage: AC220V 50Hz

Working pressure: 0.5 ~ 0.6MPa (stable, clean and dry)

Rated power :1.8KW

Machine function: Wire cutting, peeling at both ends, half stripping at one end, single end pressing and double end pressing.

Cut length:26mm~9999mm

Cutting line tolerance: Less than or equal to 1m, ± 0.02%

Stripping Length: 0.5mm ~ 35mm (more than 12mm needs half stripping)

Cutting speed: 5500 pieces / h (within 100 mm)

Processing efficiency: 4000 ~ 4800 / h (within 30 ~ 200 mm)

Tap pressure: Standard 2.0T, other pressure can be customized

Wire Range :AWG30#~14#

Applicable mould: OTP horizontal mold, straight mold (European mold can be customized)

Electric machinery :5 sets of domestic servo motor + 2 sets of stepper motor

Screw rod: 4 sets of TBI screw

Slide rail :7 sets of silver guide rail

Bearing: SKF, Sweden

Terminal pressing capacity: 2T / 3T European precision frequency conversion terminal machine

HOT-SALE PRODUCT

Quality First, Safety Guaranteed