Our Products

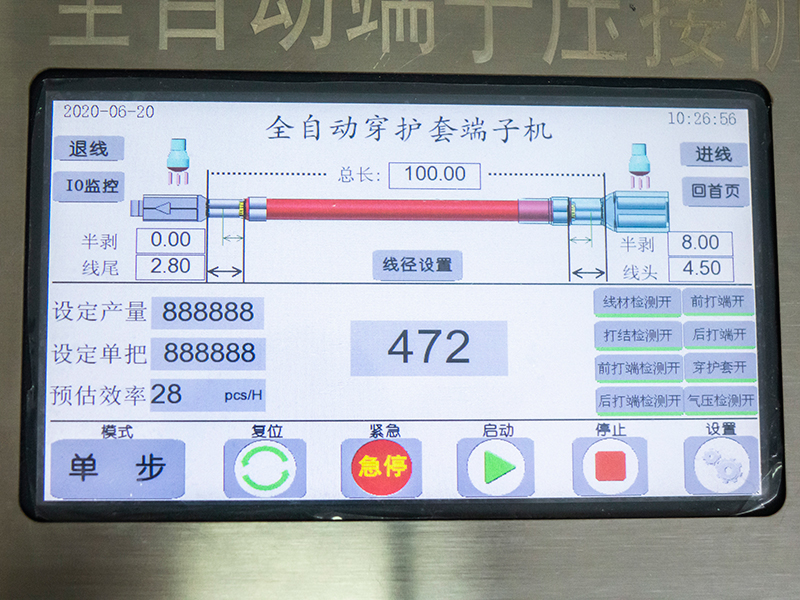

Fully automatic double-headed sheathed terminal crimping machine LJL-H01

products video

Features

1. This machine adopts imported top-level configuration: Japan Mitsubishi PLC control, servo motor, man-machine interface,

Japan SMC pneumatic components, Japan THK track, Japan Xinbao reducer, Japan Omron and Keyence sensor;

2. Double-head cutting and stripping single-head wearing waterproof plug double-headed terminal,

wearing pull sheath, peeling, cutting strip,easy to operate;

3. With stripping abnormality, pressing abnormality, air pressure anomaly detection device, to achieve true full automation.

Speed up to 1700 / hour.

Specifications&Parameters

| Model | LJL-H01 |

| Size | 750mm*1000mm*1600mm |

| Weight | 350kg |

| Power | AC 220V 2.5Kw |

| Air pressure | 0.5-0.7MPa |

| Pressure force | 2-3T |

| Control mode | PLC control |

| Terminal mold | OTP card type universal mold and other mold |

| Adaptive sheath | 187, 250, 110, etc |

| Production capacity | 1700pcs/h within 300mm (machine speed and length,wire material, terminals are related,

the actual speed needs to test customer wire) |

| Applicable wire | AWG16-24#,1007,Single wire. |

| Terminal range | all continuous terminals (disc terminals) |

| Cutting range | 50-9900mm standard(other requirements can be improved) |

| Cutting accuracy | ±0.1mm+cut length less than 0.2% |

| Detection device | low air pressure detection, stripping, pressure terminaldetection, feeding failure, elimination of all bad all

abnormalities, will be displayed on the frequency screen; can be installed according to customer requirements to install the pay-off frame and pressure management device. |

HOT-SALE PRODUCT

Quality First, Safety Guaranteed