Our Products

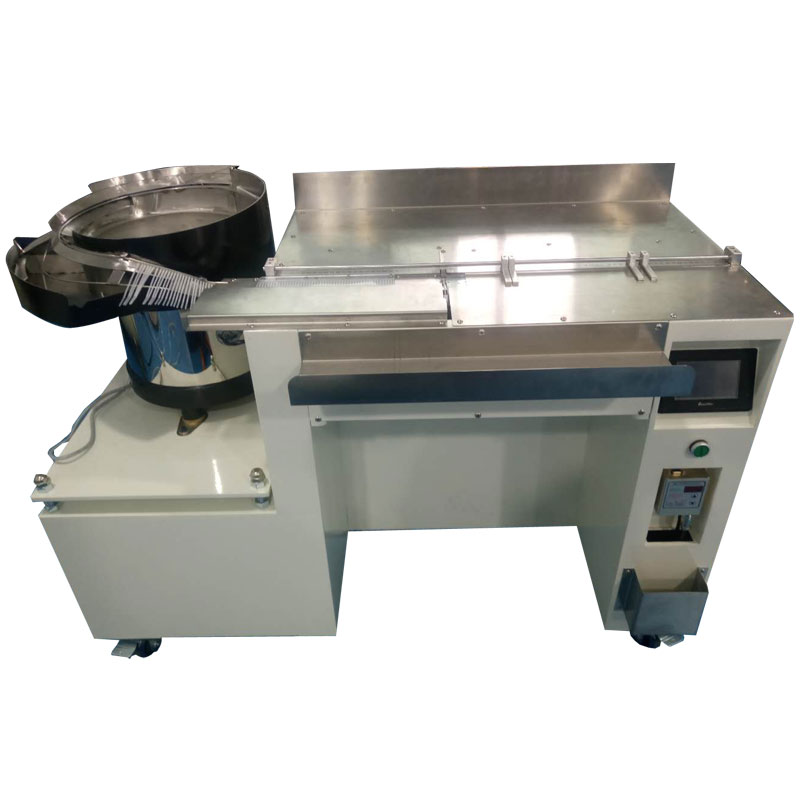

Desktop Automatic cable tie nylon machine

Automatic self-locking plastic nylon cable tie machine

Suitable:

Binding wire machine for PLC, text control circuit, working stability is good; , simple and convenient operation, set up and run the related parameter values can be directly in the PLC screen display, clear and intuitive, high degree of automation, good coherence, fast speed, free to set binding wire length, intelligent automation, only need to put around the good material in binding wire mouth, machine automatic induction tie wire, binding wire finish in one second, replace manpower binding wire, solves the manual binding with the tie is not neat, the line size is differ, the slow speed, etc. Reduce damage, reduce fatigue, this device can save more than 30% of the workforce, significantly improve the working efficiency, solved the difficult problem of employment.

Widely used in electronics factory, bundled TV, computer and other electrical internal wiring, lighting, electrical, electronic toys and other products within the line fixed, mechanical equipment, oil pipeline fixed, the ship on the cable line solid. Car packaging or bundled with other objects, can also be used for wire, air conditioning capillary, toys, daily necessities agriculture, gardening, handicrafts and other bundled items.

Product features:

1. The automatic PLC touch screen control circuit is simple and convenient to operate and has good stability.

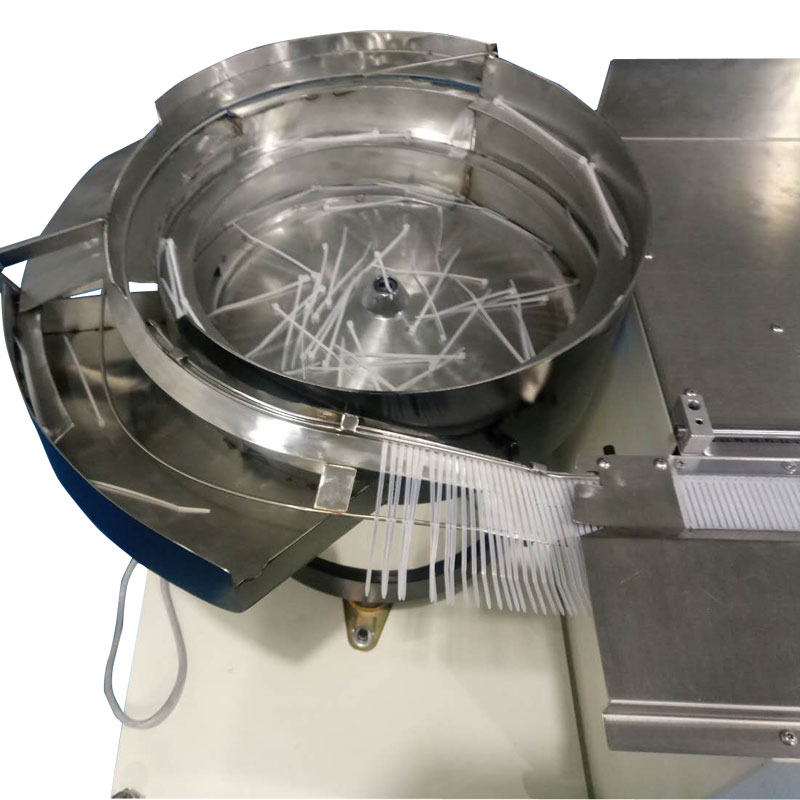

2. Bulk nylon tie belt can be loaded automatically, and manual discharging is not complicated.

3. The automatic locking and cutting tie strip can save time and effort and improve the working efficiency by about 1500 pieces / hour (depending on the product).

4. Digital adjustment of tension touch screen of tie belt.

5. Digital adjustment of the touch screen with tie tape and tail.

| Model | LJL-60Q/80Q/100Q/120Q/150Q |

| Power supply | AC220V/110V 50/60HZ |

| Suitable tie size | 60 mm / 80 mm / 100 mm/120mm/150mm cable ties |

| Application | AC/DC line, headphones line, mouse,, power cord,keyboard etc |

| Feature1 | easy operate, stable speed, cable length can be adjusted. |

| Feature2 | W-GEAR, NMRV-40 imported aluminium three-phase conver frequency motor |

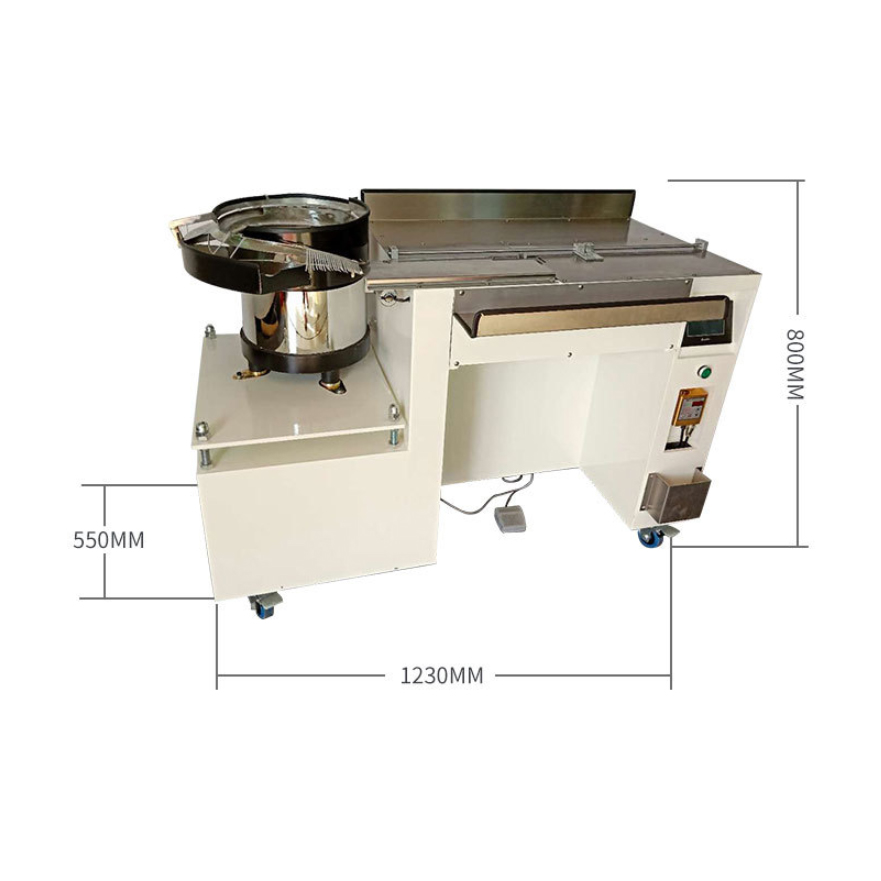

| Dimensions | L1230*W550*H800mm |

| Weight | 150KG |

HOT-SALE PRODUCT

Quality First, Safety Guaranteed