Our Products

Best Price on Laser Tube Cutting - Automatic Corrugated Pipe Cutting Machine LJL-B100 – Lijunle

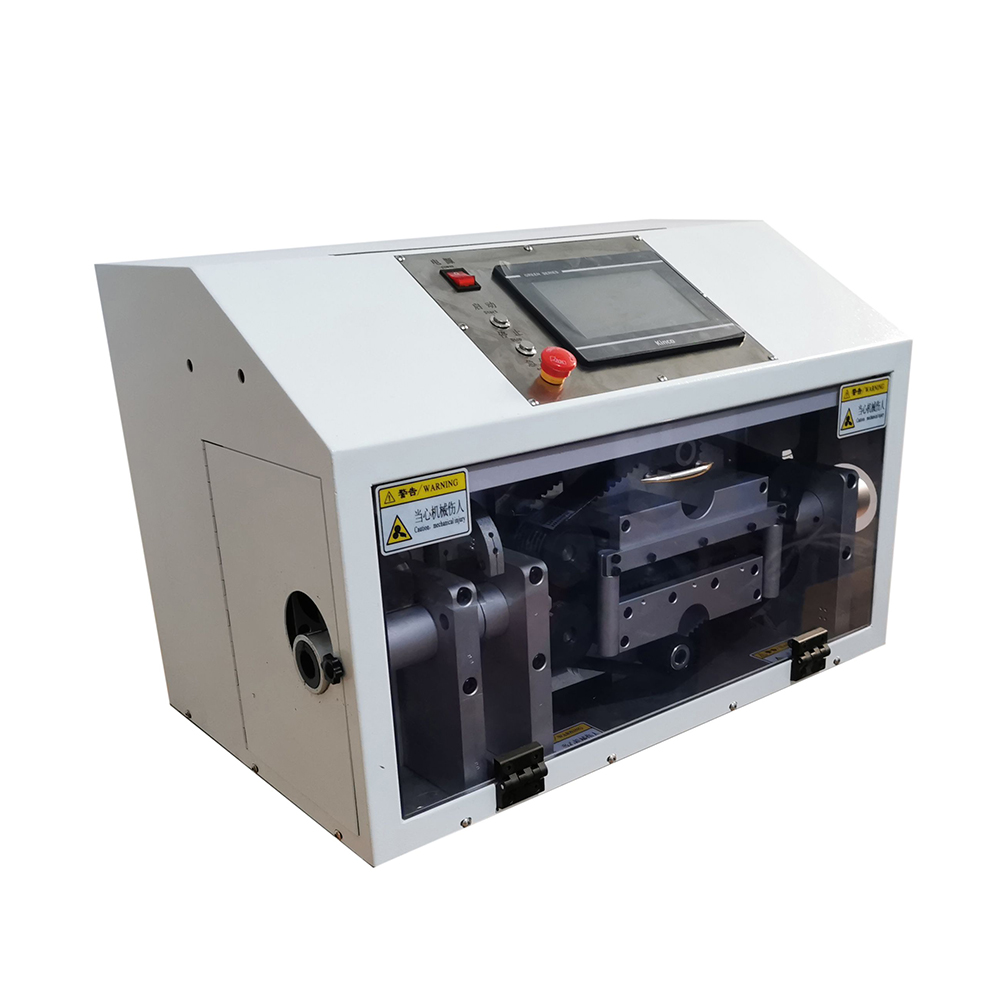

Best Price on Laser Tube Cutting - Automatic Corrugated Pipe Cutting Machine LJL-B100 – Lijunle Detail:

|

Model |

Automatic Corrugated Pipe Cutting Machine LJL-B100 |

|

Voltage |

AC220V |

|

Power |

560W |

|

Gross weight |

78kg |

|

Net. Weight |

66kg |

|

Cutting speed |

60-210pcs/min |

|

Accuracy |

±0.1mm |

|

Cutting length |

0.1-99999.9mm |

|

Cutting diameter |

38mm |

|

Dimension |

650*480*420mm(L*W*H) |

Products brief instruction of Automatic Corrugated Pipe Cutting Machine

This machine bellows development and design specifically for automotive wiring harness industry,high-precision PLC control, easy to understand, fully automatic computer cutting machine can be used for round plastic hoses, bellows cutting, processing efficiency, stable and reliable, using a stepper motor feeding, with a stable feeding, the length of the precise characteristics.

Characteristic description of Automatic Corrugated Pipe Cutting Machine

1. This machine is designed for a series of thick pipes, corrugated, silicone, rubber, oil seal, coffee, medical, gas, pipes, etc., using crawler delivery control with high precision and fast speed.

2.The cutting device adopts beautiful work knife design, smooth cutting, low cutting cost, simple and easy to replace.

3. Use the stepping motor to deliver feeding, with the characteristics of stable feeding and accurate length. The circuit adopts high-precision single-chip computer integrated control, simple operation, stable control, the screen adopts the touch screen color screen display, all kinds of data are clear at a glance.

User-friendly software design-the whole computer set various specifications, retreat materials rotary switches, knobs and Conveyor belt rising and falling blade replacement.

The total number of the whole entire computer operation–settings pipe cutting machine work, singular, after reaching a predetermined number of jobs, cut the tube will stop working; proportion of adjustable length, Send acceleration, cutting speed, can debug.Pipe cutting machine continuously working properly.

Past and design philosophy–in line with international standards of universal terminal machine, easy to operate, can quickly replace the mold, technical standards for operating personnel Requirements to a minimum, reduce personnel management costs.

Product detail pictures:

Related Product Guide:

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for Best Price on Laser Tube Cutting - Automatic Corrugated Pipe Cutting Machine LJL-B100 – Lijunle , The product will supply to all over the world, such as: Bahrain, Spain, Hamburg, Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed