Our Products

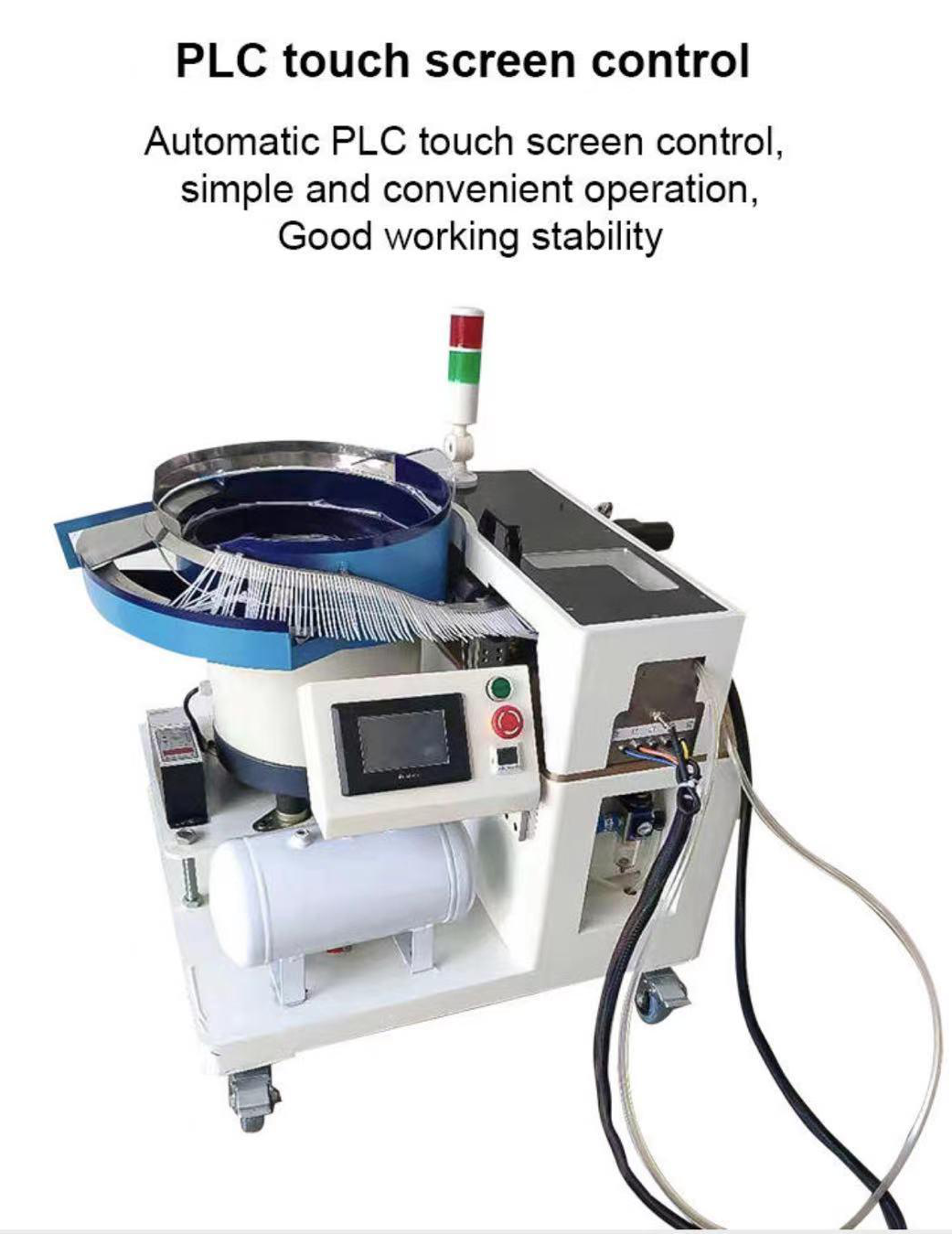

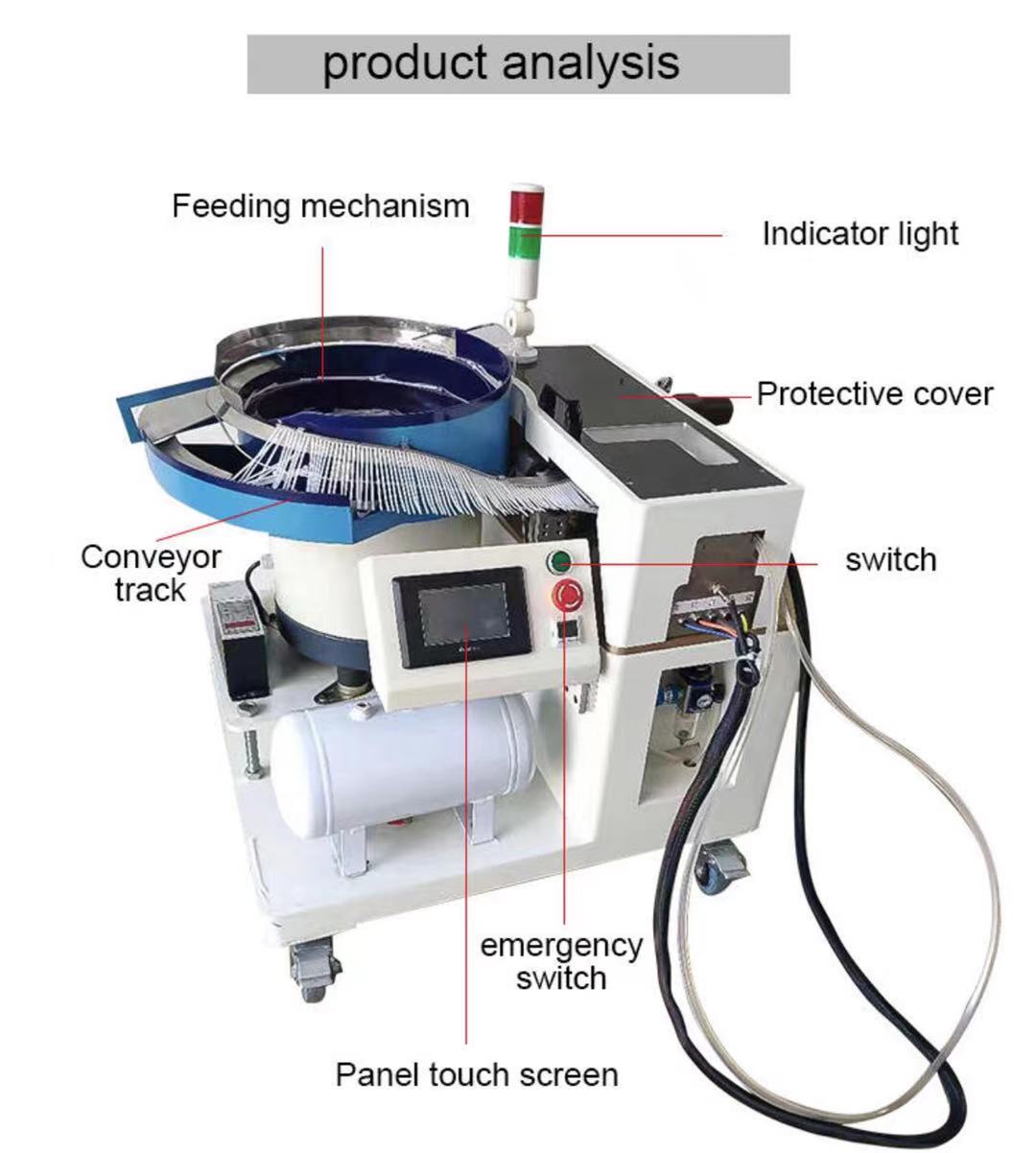

Automatic cable tie gun machine/Handheld wire tying machine LJL-80S

products video

Features

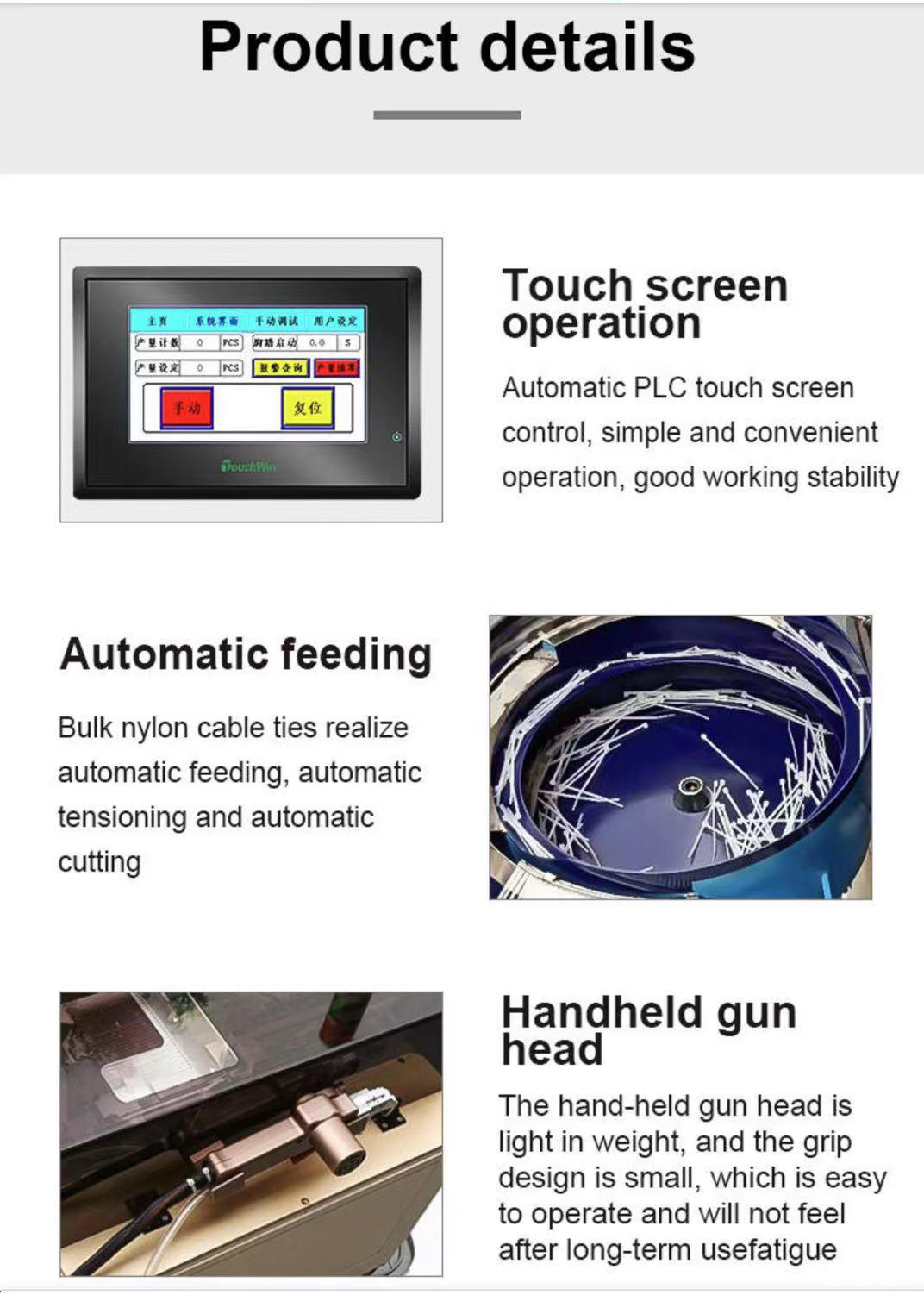

1. The automatic PLC touch screen control circuit is simple and convenient to operate and has good stability.

2.Bulk cable tie at random in the rotary table will be chaos, cable tie through the pipeline to puff

3.Automatic shuttle tie cable tie, automatic tip.Time, improve work efficiency

4.Handle design compact, easy to grip

5.Banding strength or tightness can be adjusted through the knob

Specifications

| Model | LJL-80S/100S/ 120S/150S/200S |

| Power supply | AC220V/110V 50/60HZ 400W |

| Suitable tie size | 100mm/120mm/150mm/200mm cable ties |

| Air express | 0.65Mpa±0.5 |

| Application | AC/DC line, headphones line, mouse,, power cord,keyboard etc |

| Feature1 | easy operate, stable speed, cable length can be adjusted. |

| Feature2 | W-GEAR, NMRV-40 imported aluminium three-phase conver frequency motor |

| Dimensions | L 720*W 660 *H780mm |

| Weight | 130KG |

Function

1.Disorderly bulk cable bands flow into random vibrating plates, which are ducted to the tip

2. Pull the trigger, automatic feeding, tape, tightening, cutting, polishing waste and other actions;

3. 0.7 seconds, including feeding, tape, tightening, cutting, polishing waste, and including auxiliary time for a total period of approximately 1.3 seconds. A machine can replace 7-8 workers.

4. Waste automatically collected in waste tanks through a special recycling system (optional);

5. Hand-held tip light, compact design grip, easy to hold, long use will not feel tired;

6. The binding strength or tension can be adjusted by the knob;

7. The host has its own PLC control system, and the touch screen displays in Chinese and English, with simple operation;

8. It can be used in cooperation with the robot on the automatic production line to realize the automatic cable tying, and it can also be fixed on the table as a desktop cable tying machine.

Safety precautions

1. External power supply: stable 220 V, 50-60 Hz single phase power supply.

2. For safety, the machine is equipped with a protective shell. Non professionals are not allowed to open it at will. During the operation of the machine, operators are strictly prohibited to put their hands on the wire hook without protective shell to avoid hand injury.

3. As the device is controlled by touch screen, the technician should turn off the power when adjusting the machine, so as to avoid other people touching and starting the machine by mistake.

4.In case of machine failure, your company’s maintenance personnel can not eliminate it, please inform our company in time for maintenance.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed